Additive Manufacturing and Industrial 3D Printing

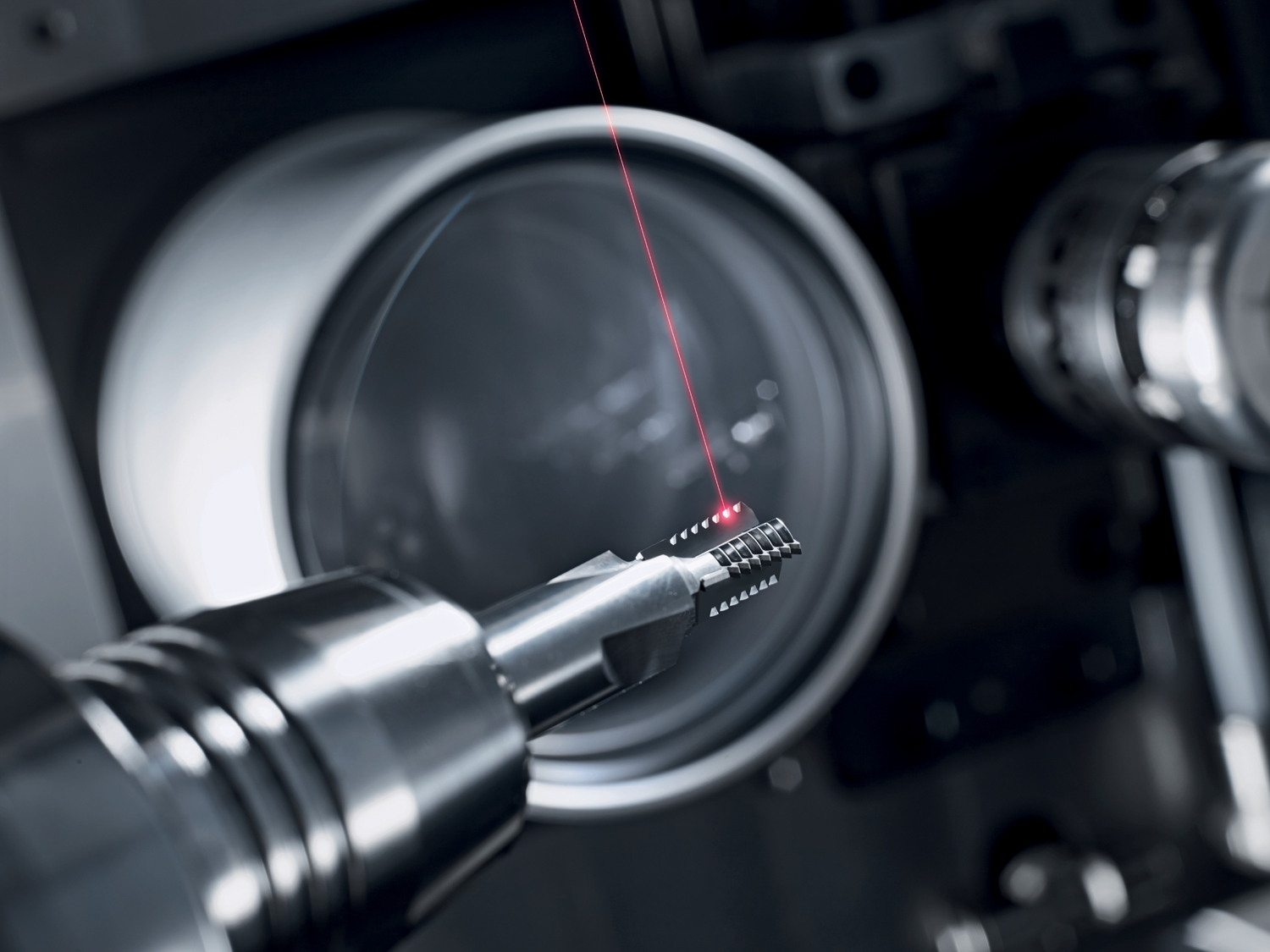

Additive Manufacturing (AM) produces components from metal, plastics and synthetic resins. This is done by laser-based methods such as:

- Laser Powder Bed Fusion, LPBF

- Stereolithography

- Laser sintering

Typical applications are rapid prototyping and industrial series production of 3D printed parts.

Support Through Scan Systems

The following sections highlight typical goals of LPBF machine builders and help select the right SCANLAB solution for them.

Increase in productivity

| Goal | Possibilities | SCANLAB solutions |

| Shorter production time |

Increase throughput with multi-head laser machines through simultaneous processing and high overlap of the image fields. |

|

| Large construction fields | Scan system configurations with flat field correction | |

| Minimization of process non-productive time |

Reduction of skywriting times und undesired laser-off times through control with SCANahead-technology |

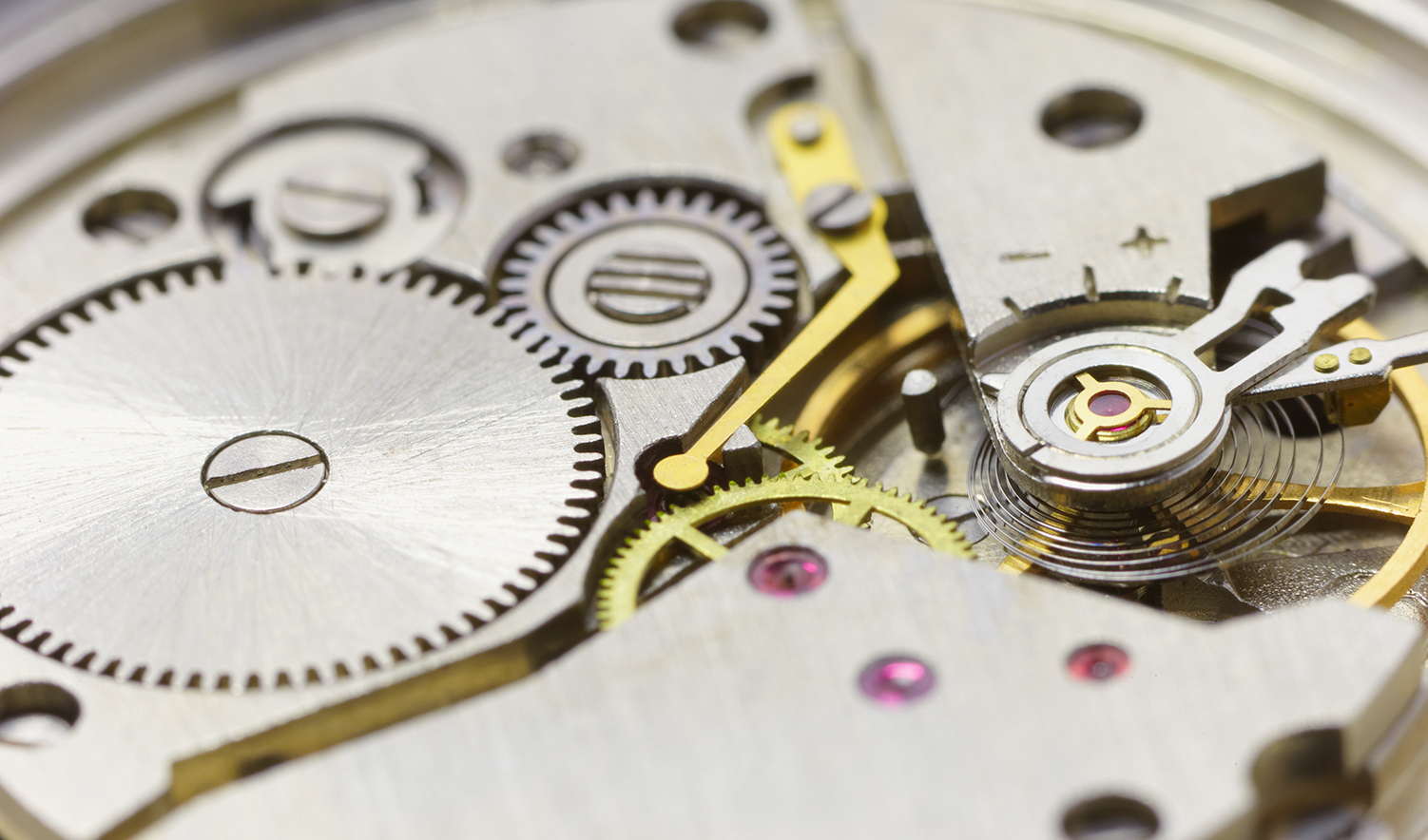

Production of filigree and complex structures

| Goal | Possibilities | SCANLAB solutions |

| Highest accuracy and low drift |

Galvanometer scanner with se encoder technology for system stability even with long production times |

Systems with se encoder technology, for example: |

| Compensation of machine-specific tolerances | Software solutions for the calibration of 2D or 3D scan systems |

Reliable process results

| Goal | Possibilities | SCANLAB solutions |

| Precise position monitoring |

Enhanced process monitoring by assigning sensor signals to the location in the construction field where they were recorded |

|

| First Time Right |

Monitor and control work results in real time with process control that interacts with process sensor technology (e.g. pyrometer) |

Suitable Scan Systems

Suitable Control Solutions

Solutions for Additive Manufacturing

Laser Scan Systems and Control Possibilities

Laser Applications Freely Cross Industrial Boundaries

Laser processing methods are employed in numerous industries. Click a specific industry link to see a selection of processing methods that use galvanometer scanners.