Lasers Are Industry's Flexible Tools

Lasers are indispensible to today's mechanical engineering industry, thanks to their quality, flexibility and automation possibilities.

Lasers offer a wide array of materials-processing applications to the tool and mechanical engineering sector:

-

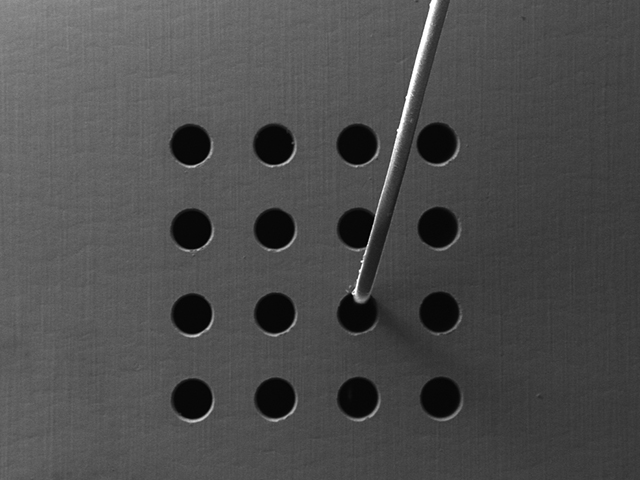

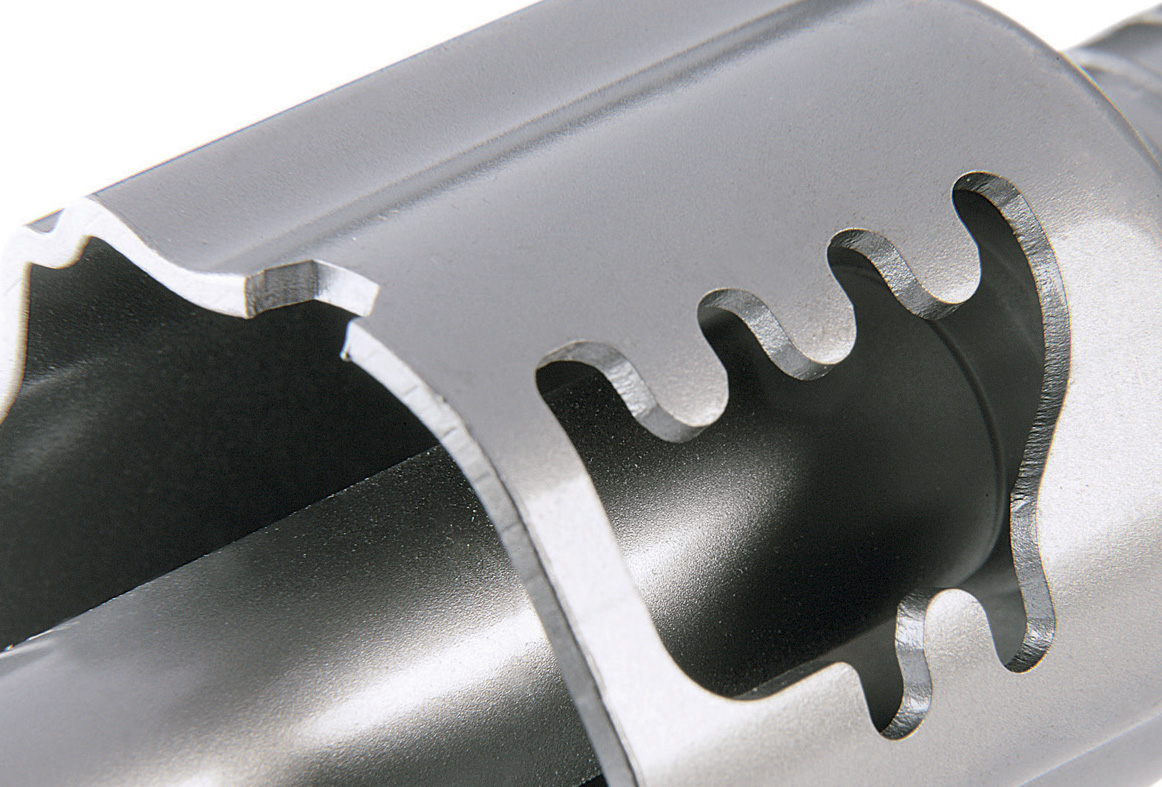

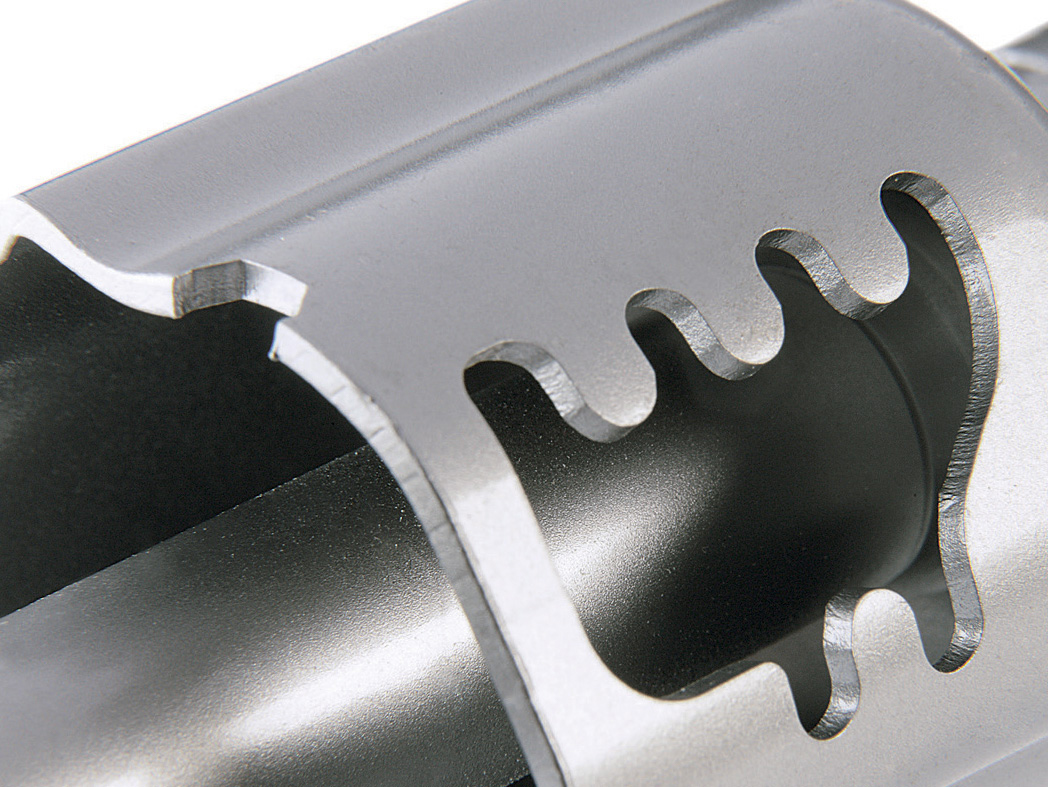

Laser cutting and punching of components, contours and stencils

-

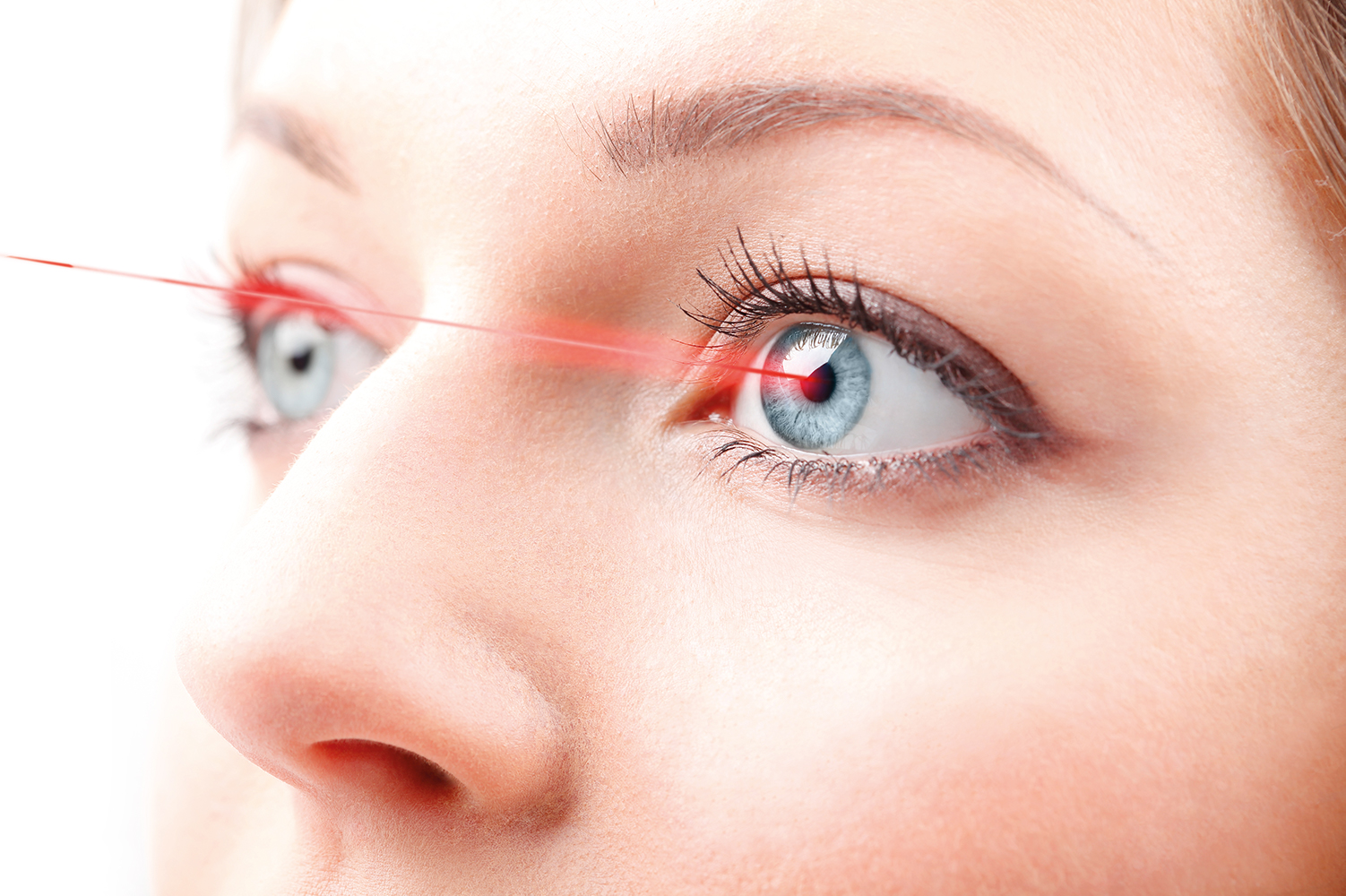

Laser marking of raw materials and final products, environmentally friendly and durable marking, even of poorly accessible component surfaces

-

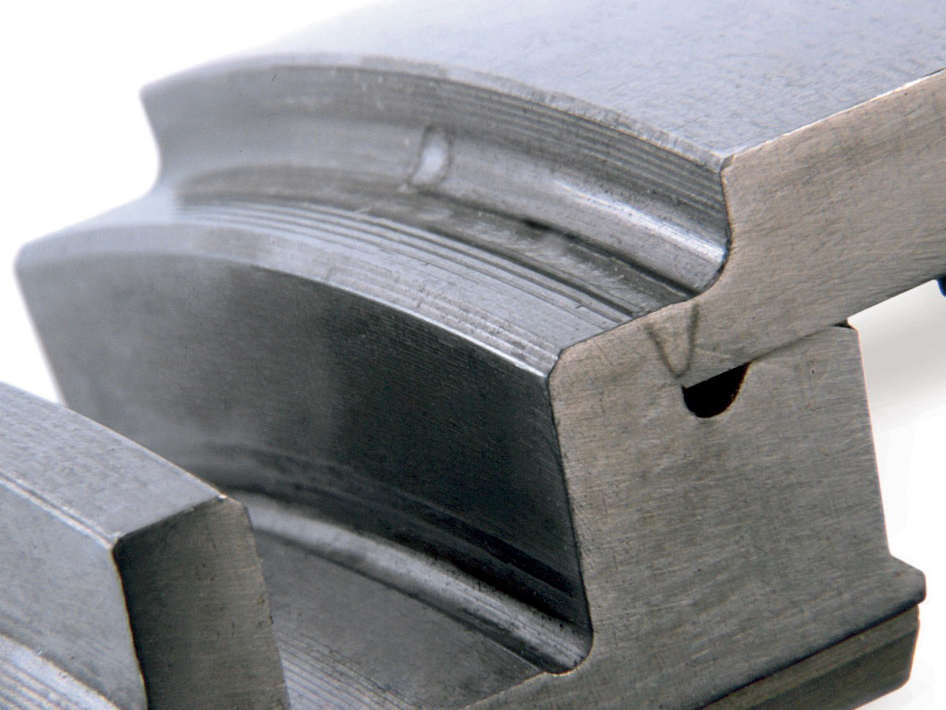

Laser engraving and deep engraving for generating 3D structures via layered ablation, e.g. for injection molds or embossing tools

-

Laser welding for durable and clean joined component edges

-

Laser sintering for rapid prototyping (additive manufacturing, 3D printing) quick product development, small-scale production and manufacturing composite components

-

Laser hardening targeted surface treatment for minimized wear

-

Laser cleaning of industrial surfaces to remove organic and anorganic contaminations such as rust and oil

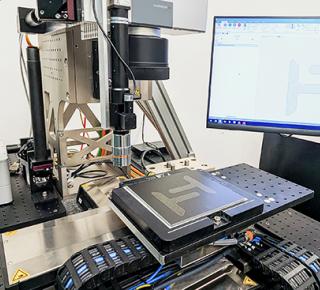

Lasers as Tools

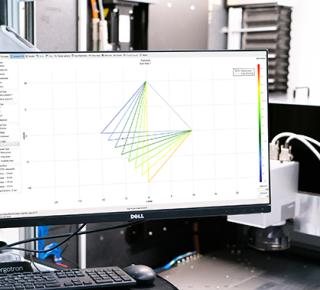

By transforming lasers into universal tools, scanning solutions help to add functionality and value to materials. SCANLAB's broad palette of scanning solutions fulfills demands for higher speed, more precision, greater efficiency or improved environmental compatibility.