Countless Marking Options

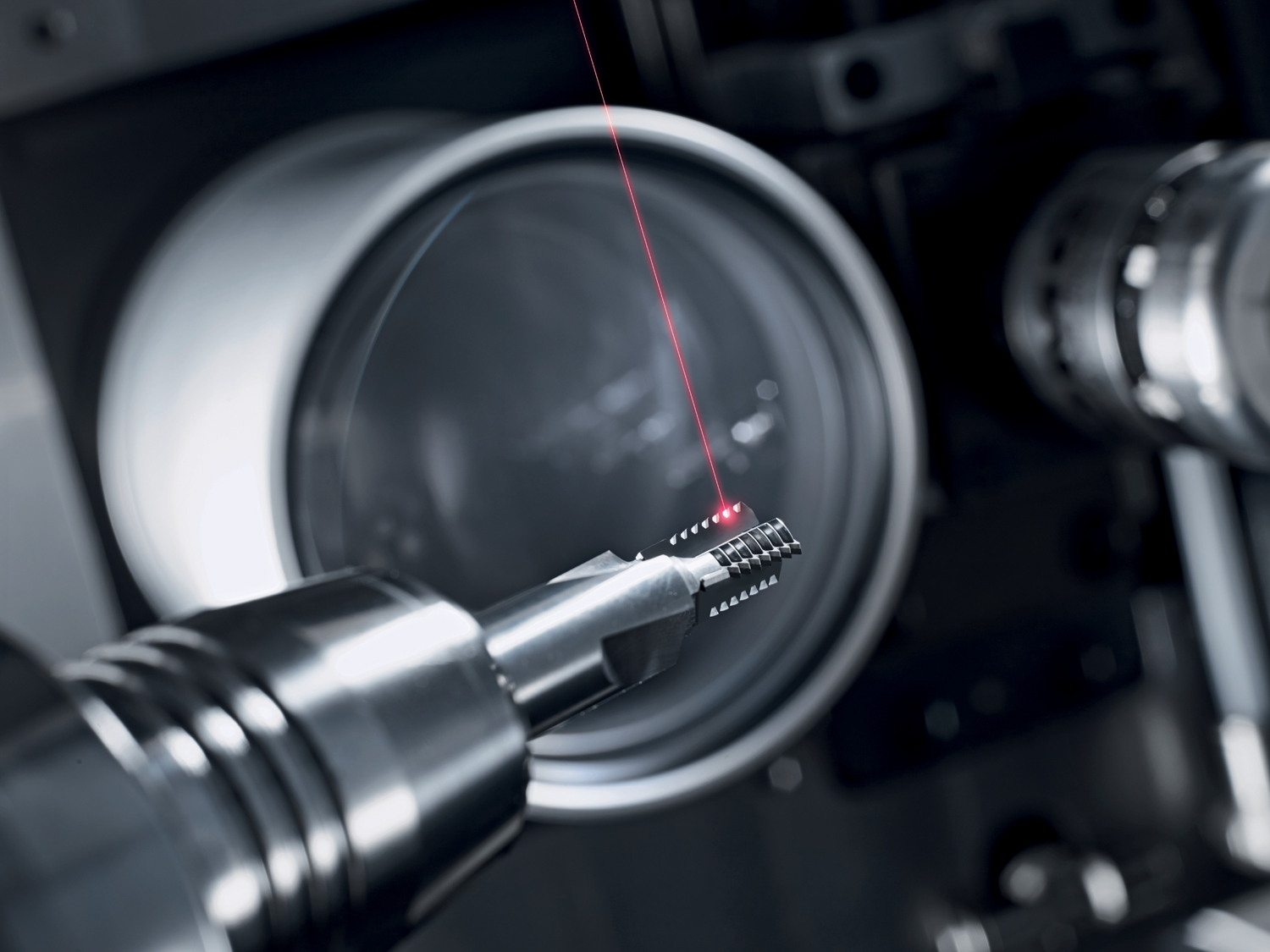

Laser marking is the foremost industrial application in which scan systems transform lasers into efficient tools. A boundless variety of marking applications owe their existence to scan systems and the cost-effectiveness achieved by their dynamic performance, precision and speed.

Lasers can mark paper, metal, plastics and countless other materials. The markings are extremely durable and waterproof, while resisting smudges, solvents and abrasion. And laser marking offers outstanding design flexibility, because no molds or stencils are required. Plus, the process is contactless and wear-free.

Their specific functionality makes scan systems uniquely suited for numerous laser marking applications.

Laser Marking with Dynamic Data and 'On-the-Fly'

Scan systems allow efficient, individualized labeling of components using dynamic data such as serial numbers, QR codes, dates, tracking numbers or data matrix codes generated via an automated production process.

An innovative control concept eliminates computation-related time delays to enable real-time, on-the-fly processing.

Laser Marking Special Effects

Exceptional marking permanence is achieved by marking directly on the material's surface. And razor-sharp, deep-black characters can be generated.

On plastics, carbonization-induced printing special effects are creatable in high volume – with abrasion resistance well-suited for depicting personal data, photos or numbers (e.g. on objects such as ID cards).

Laser Perforating and Laser Scribing

The packaging industry makes abundant use of laser perforation applications, ranging from fine holes for freshness-packaging gas exchange, all the way to tearing aids in various packagings applying laser scribing.

Here, scan systems provide flexibility needed for diverse structures and designs, as well as the dynamics necessary for high-volume manufacturing.

Combining Laser Processes (e.g. Laser Labeling with Cutting)

Lasers and scan systems enable single-operation execution of combined laser processes, e.g. simultaneous printing and contour-cutting of nameplates, safety labels or stickers.

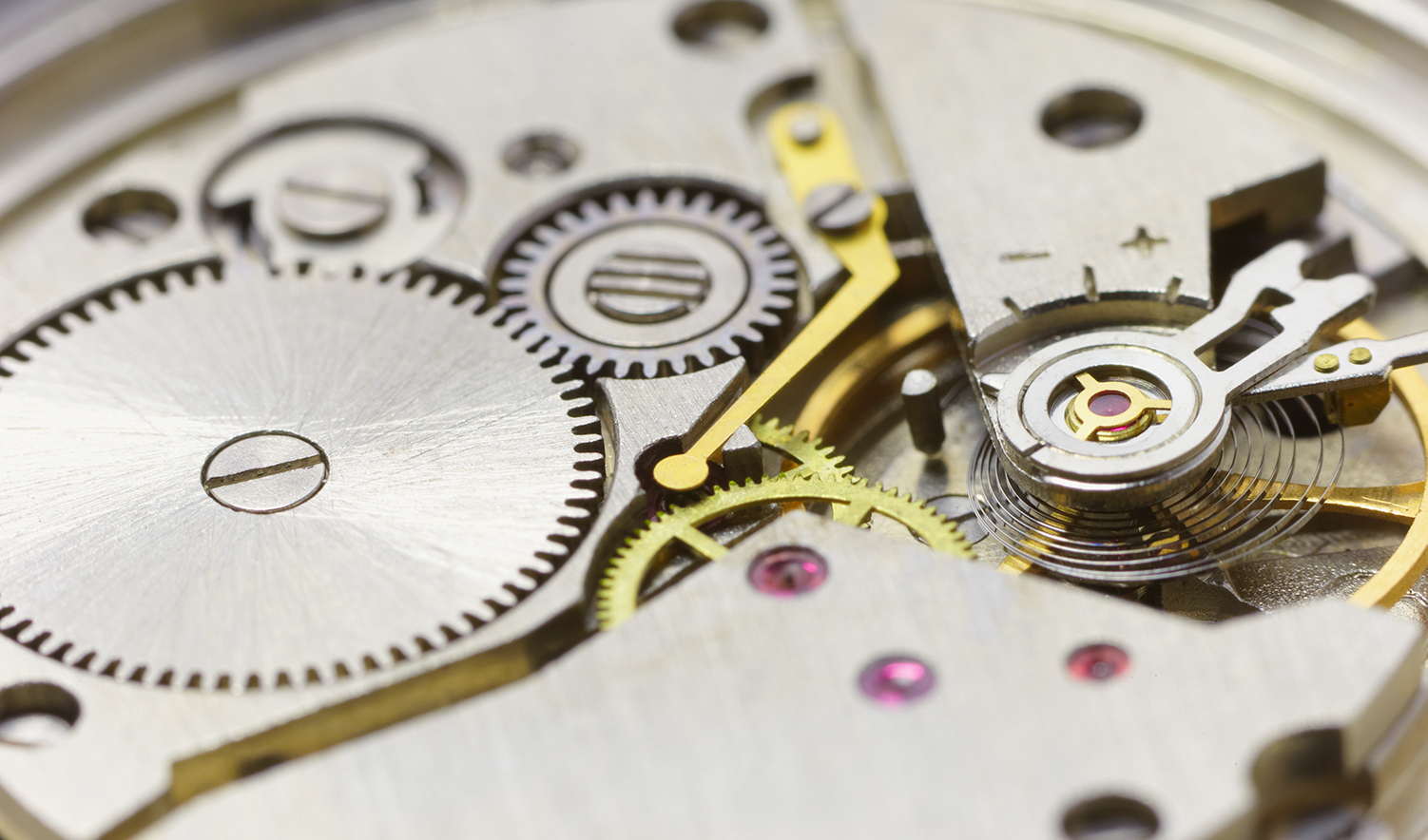

Control Elements with Day/Night Marking

The manufacture of day/night control elements requires ultra-precise lacquer removal from fine structures – an application for which scan systems have set the technical standard for years.

Suitable Solutions

Laser Applications Freely Cross Industrial Boundaries

Laser processing methods are employed in numerous industries. Click a specific industry link to see a selection of processing methods that use galvanometer scanners.