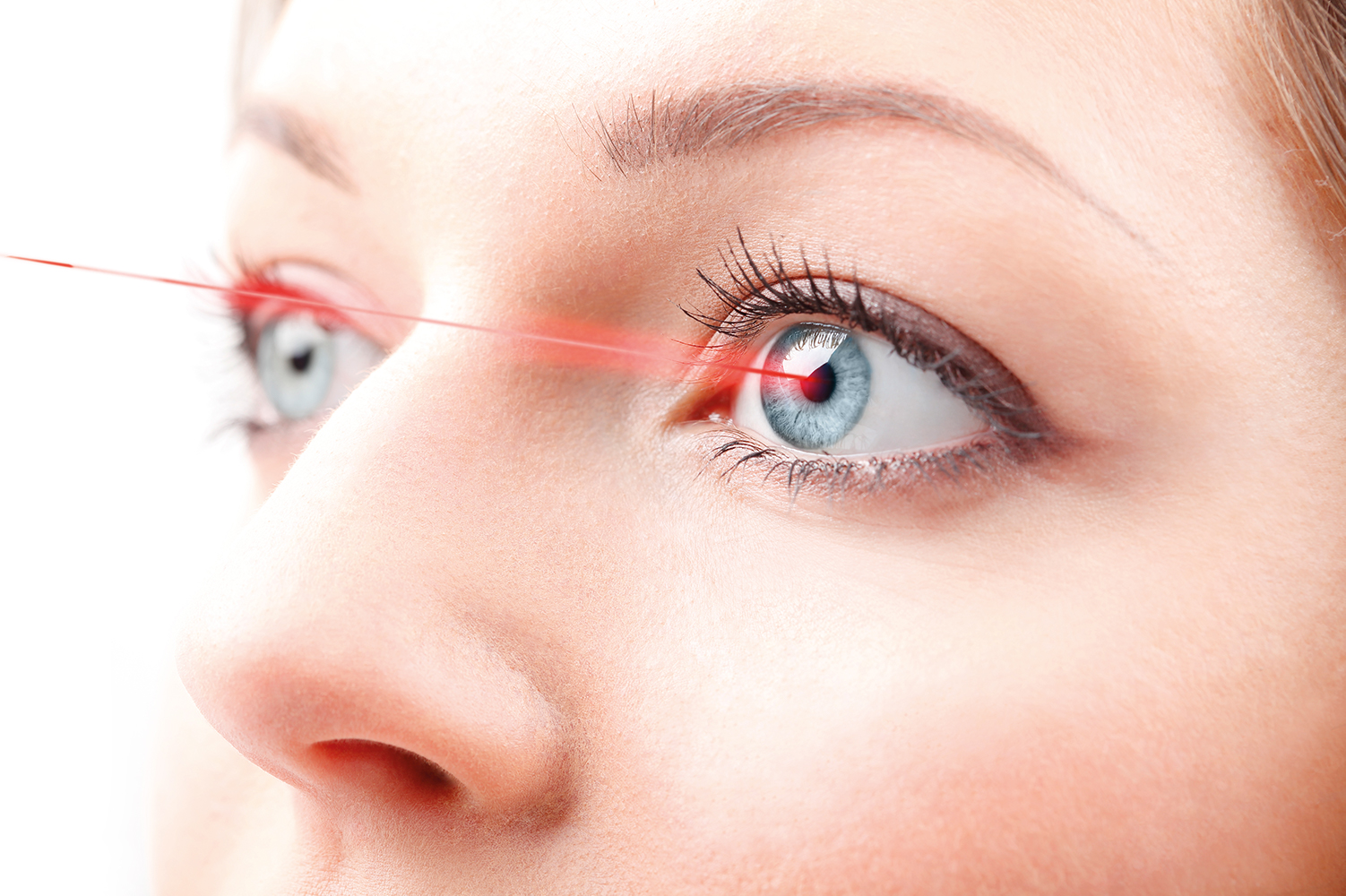

Lasers Ensure Freshness and Safety

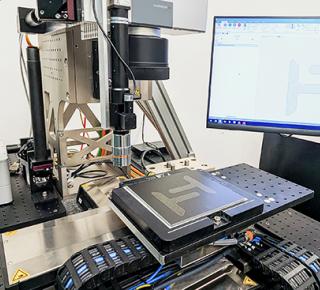

For consumer protection, country-specific labeling guidelines regulate the global distribution of food, cosmetics and pharmaceuticals. For example, packagings must clearly specify information such as ingredients, expiration dates and names of manufacturers. For increased safety, as well as product-liability purposes, a batch tracking code is required, too. Laser labeling makes this simple, hygienic and environmentally friendly.

The most modern key elements of packaging encompass functionality, appearance and feel, which in part are only attainable by laser processing.

As laser processing is 'contactless' and therefore flexible, even very small-scale production (e.g. print-on-demand labels) is economically viable.

Typical Laser Applications in the Food and Packaging Industry

-

Laser labeling and coding of a very wide range of materials and often on-the-fly (on moving objects), e.g. for reliable printing of expiration dates and batch codes

-

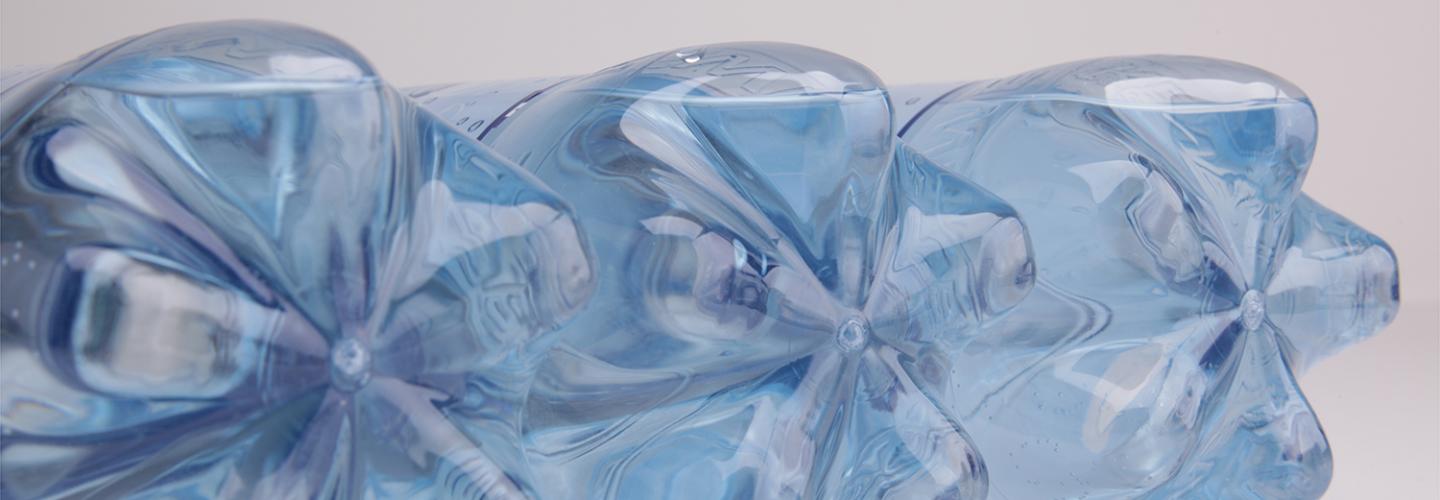

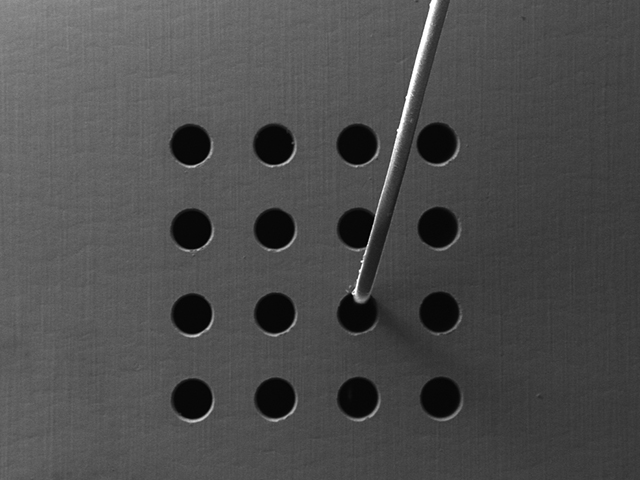

Laser perforation to extend food shelf life via improved air exchange and moisture conservation (atmosphere packaging)

-

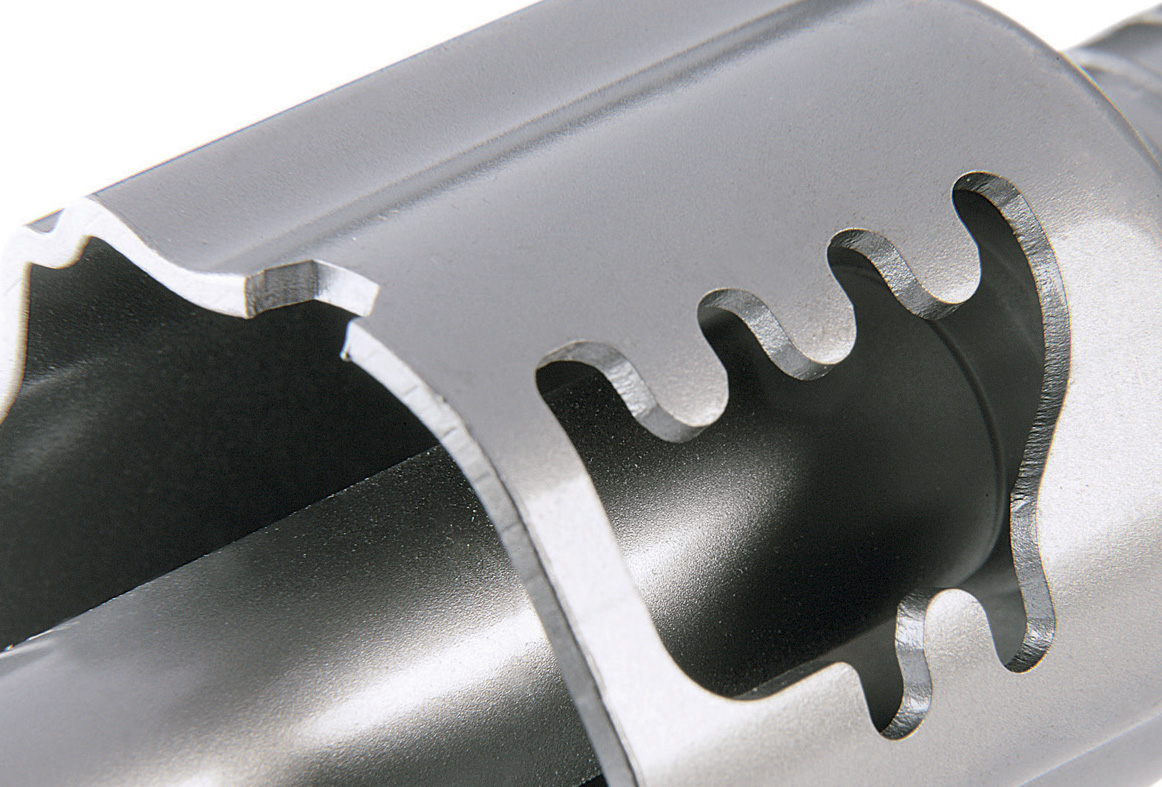

Laser scribing for easy opening of packagings

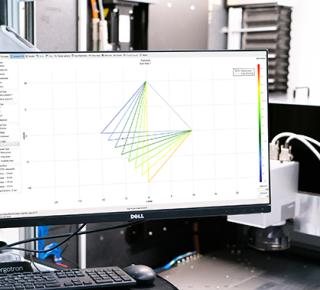

Lasers as Tools

By transforming lasers into universal tools, scanning solutions help to add functionality and value to materials. SCANLAB's broad palette of scanning solutions fulfills demands for higher speed, more precision, greater efficiency or improved environmental compatibility.