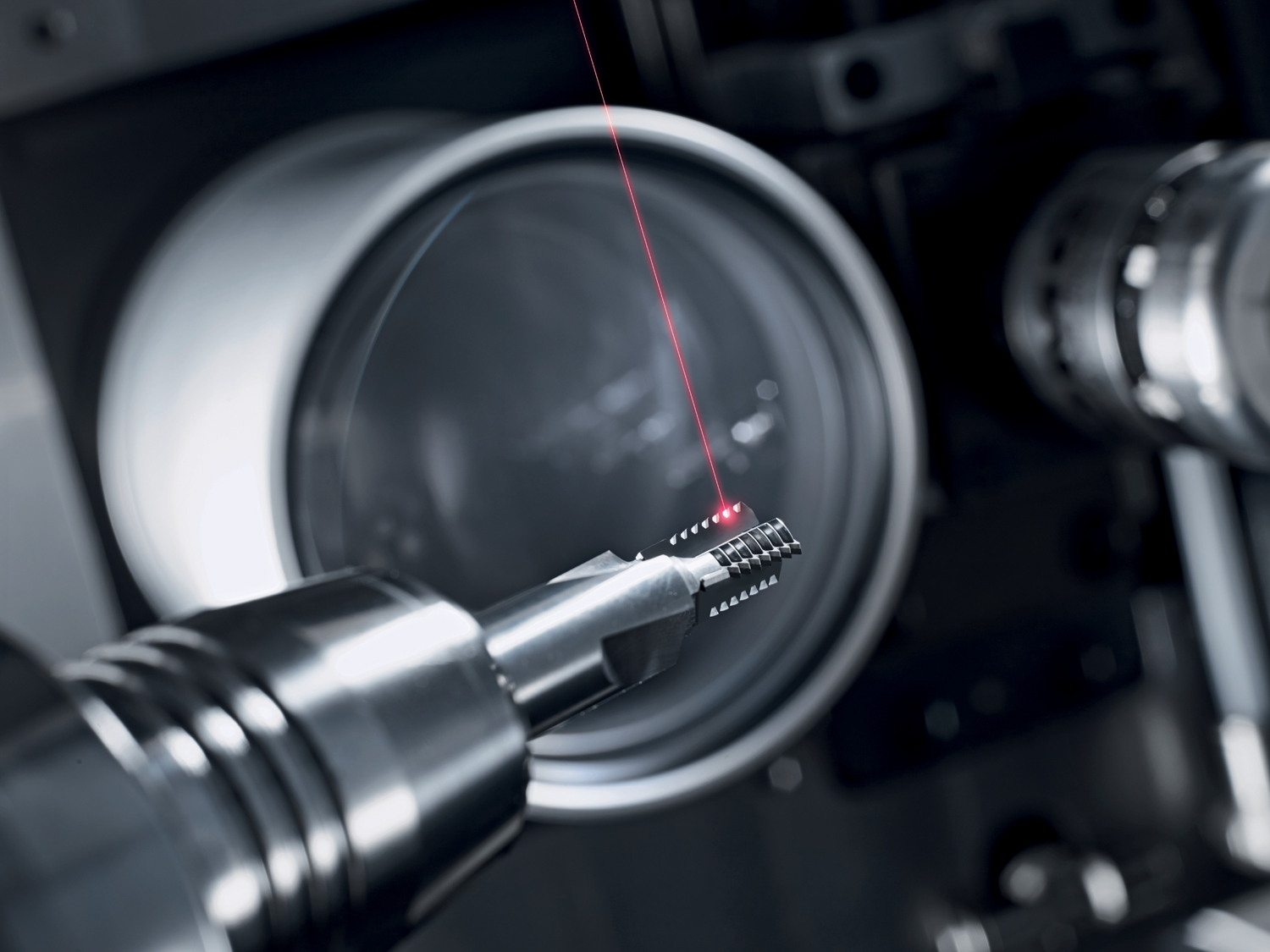

Laser Cleaning

Lasers are a universal tool with applications that include cleaning and pretreating surfaces.

More and more companies from the aerospace, automotive and e-mobility industries are now using this versatile technique. Laser surface treatment opens up a host of possibilities that extend to precision paint and rust removal, surface preparation to ensure optimal adhesion, hairpin stripping, weld-seam cleaning, and deoiling and degreasing molds and dies. In the energy sector, the laser cleaning technique is ideal for cleaning turbines and tanks. And in the food production industry, laser cleaning is used as a fast, hygienic, low-cost method for cleaning equipment such as baking tins.

Long-term benefits

The success of this technology is rooted in its wide-ranging environmental benefits and savings.

Laser cleaning is a non-contact, low-maintenance process that eliminates the need for expensive chemicals that may be harmful to health and for abrasive blasting media such as sand. As a result, the process is more environmentally friendly and uses less energy.

The use of a laser in combination with an intelligent actuation approach allows for the precise, controlled removal of selected, individual layers to produce specific textures on the surface that is being cleaned. Alternatively, the laser can be used to remove material very evenly from the surface being cleaned, achieving superbly uniform cleaning results.

The entire process of cleaning the workpiece is particularly gentle because the laser parameters can be tailored to the specific cleaning application in order to remove unwanted organic and inorganic matter by means of vaporization. Depending on the application, plant manufacturers will use anything from portable, handheld devices to large, permanently installed systems.

SCANLAB caters to its integration partners' needs with a fantastic range of highly dynamic scanning systems for positioning lasers:

- SCANcube III: Scanning system for high working speeds

- intelliSCAN III: Scanning system for high working speeds with large apertures for high laser output

- Individual axes and modules for compact, portable devices

- varioSCAN: z axis for 2.5D and 3D cleaning applications

- RTC boards: Actuation solution for highly dynamic scanner positioning, which also allows for 'on-the-fly' operations

Suitable Solutions

Laser Applications Freely Cross Industrial Boundaries

Laser processing methods are employed in numerous industries. Click a specific industry link to see a selection of processing methods that use galvanometer scanners.