Laser Technolgy - Key in Solar Industries

The solar industry is committed to slashing the cost of photovoltaic renewable power further. In the manufacturing of solar modules, laser processing takes the center stage. Lasers offer additional benefits such as improving solar-cell efficiency through full-surface structuring of back contact cells.

Typical Laser Processes in the Solar Industry

-

Laser structuring Full-surface structuring of silicon wafers

-

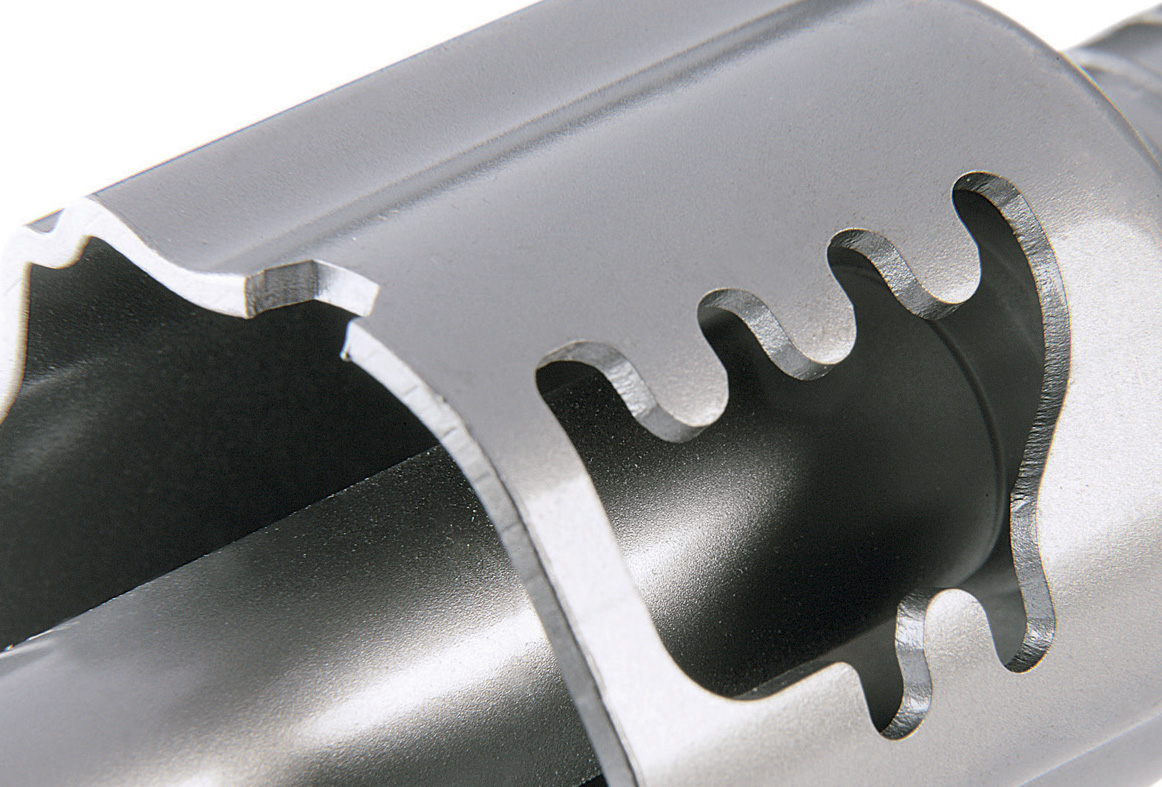

Laser cutting Fast cutting of crystalline solar cells and silicon wafers with high precision and low thermal input

-

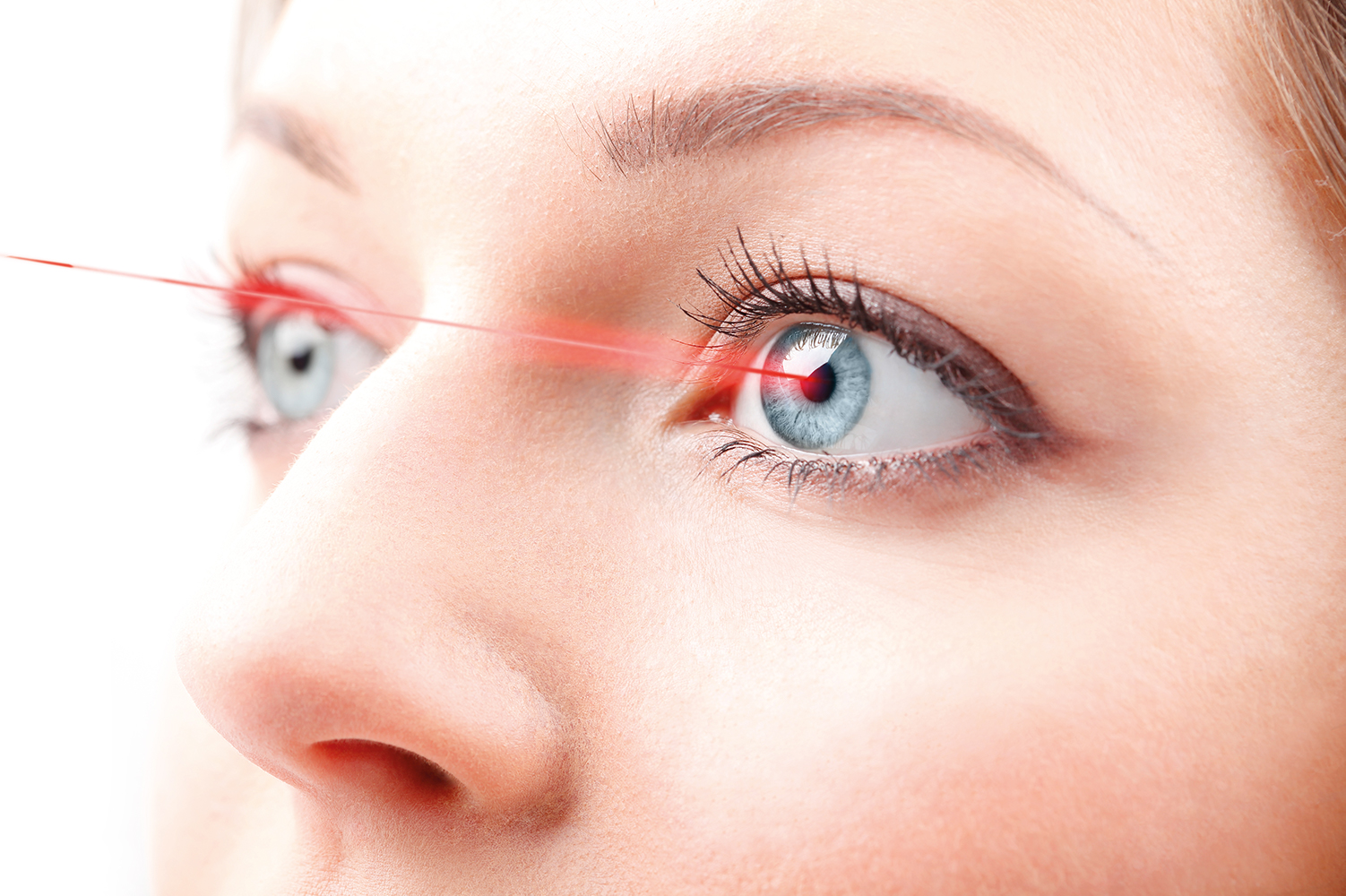

Laser junction isolation Precise, dependable electrical isolation of front and backside solar cells after doping

-

Laser-selective emitter doping Local, selective over-doping of crystalline solar cell emitters for improved efficiency

-

Soldering and welding of solar modules Fast and gentle method ideal for advanced cell designs

-

Laser marking Labeling of solar cells, e.g. for batch tracking

-

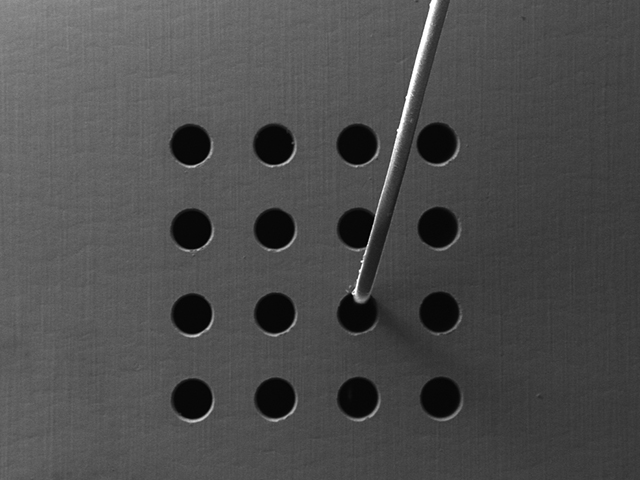

Laser drilling for back-side contacts Modern cell designs, such as Metal Wrap-Through (MWT) or Emitter Wrap-Through (EWT), use lasers to drill silicon wafers. Depending on the design, tens of thousands of bore holes are necessary.

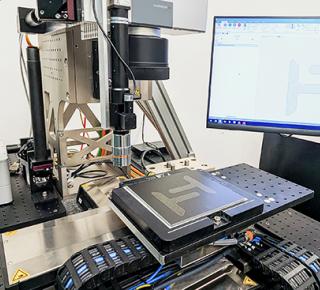

Lasers as Tools

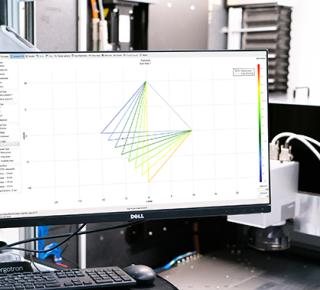

By transforming lasers into universal tools, scanning solutions help to add functionality and value to materials. SCANLAB's broad palette of scanning solutions fulfills demands for higher speed, more precision, greater efficiency or improved environmental compatibility.