Laser Processes for Clean Transportation

Electromobility (E-Mobility) is a concept that is gaining ground, and with good reason: It is a crucial component of any long-term strategy for sustainable, environmentally friendly travel. Progress in this area will not only revolutionize the automotive industry – thanks to the advent of e-bikes, e-scooters, etc. it will also reshape local travel, as well as having a significant impact on the way we conduct our leisure activities.

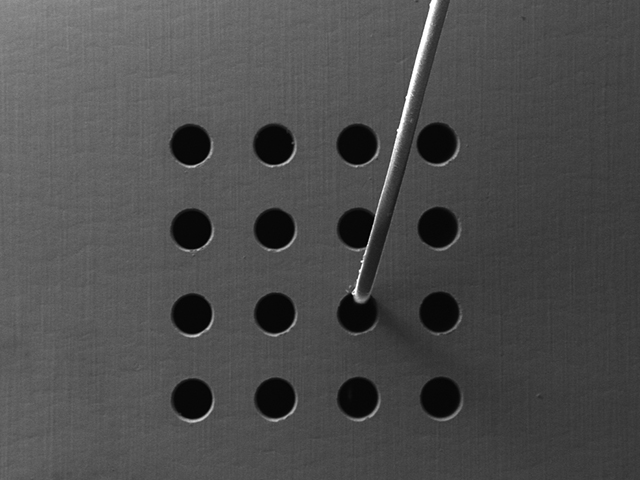

Energy storage (batteries) and weight are key considerations for all vehicles with electric motors. Lasers offer a solution to both these issues; they allow new production processes to be employed, considerably reducing costs while significantly improving quality. The use of laser technology reduces cycle times and optimizes production processes in a multitude of ways.

In the electric vehicle sector, laser beam welding is the most commonly used process that employs lasers. Its applications include:

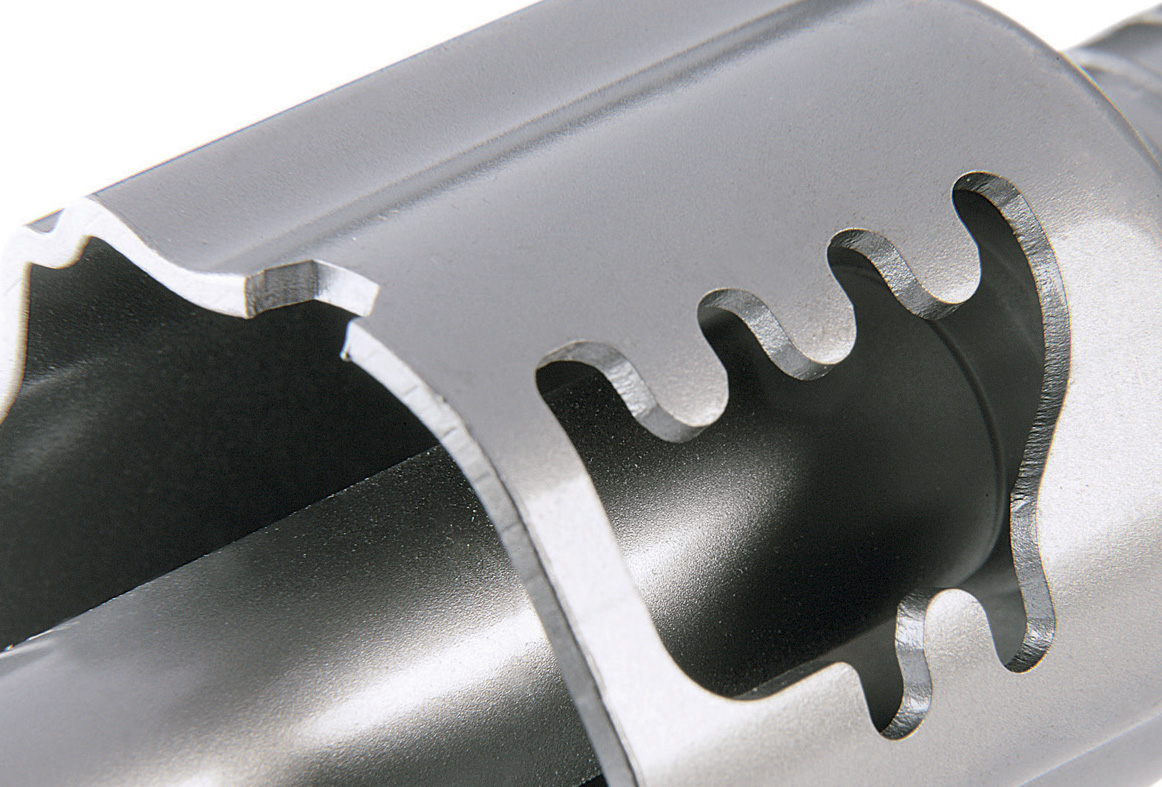

- The production of electric motors – for welding the rectangular copper wires (hairpins) in the stator instead of using conventional winding methods

- The production of batteries – for keeping battery packs together by means of tension rods, joining battery packs by means of busbar welding, welding battery trays, etc.

- Welding current-carrying components such as electronic circuits and control units

- Welding processes involving vehicle bodywork (using remote laser beam welding), including both conventional bodywork materials and lightweight materials (fiber composites)

More E-Mobility competence is offered by our sister company

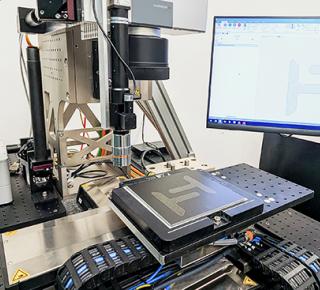

Lasers as Tools

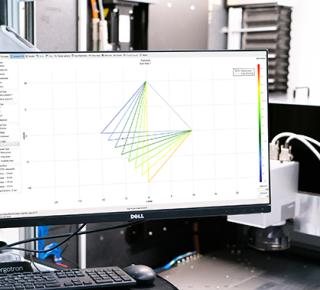

By transforming lasers into universal tools, scanning solutions help to add functionality and value to materials. SCANLAB's broad palette of scanning solutions fulfills demands for higher speed, more precision, greater efficiency or improved environmental compatibility.