Laser Technology Creates Lasting Values

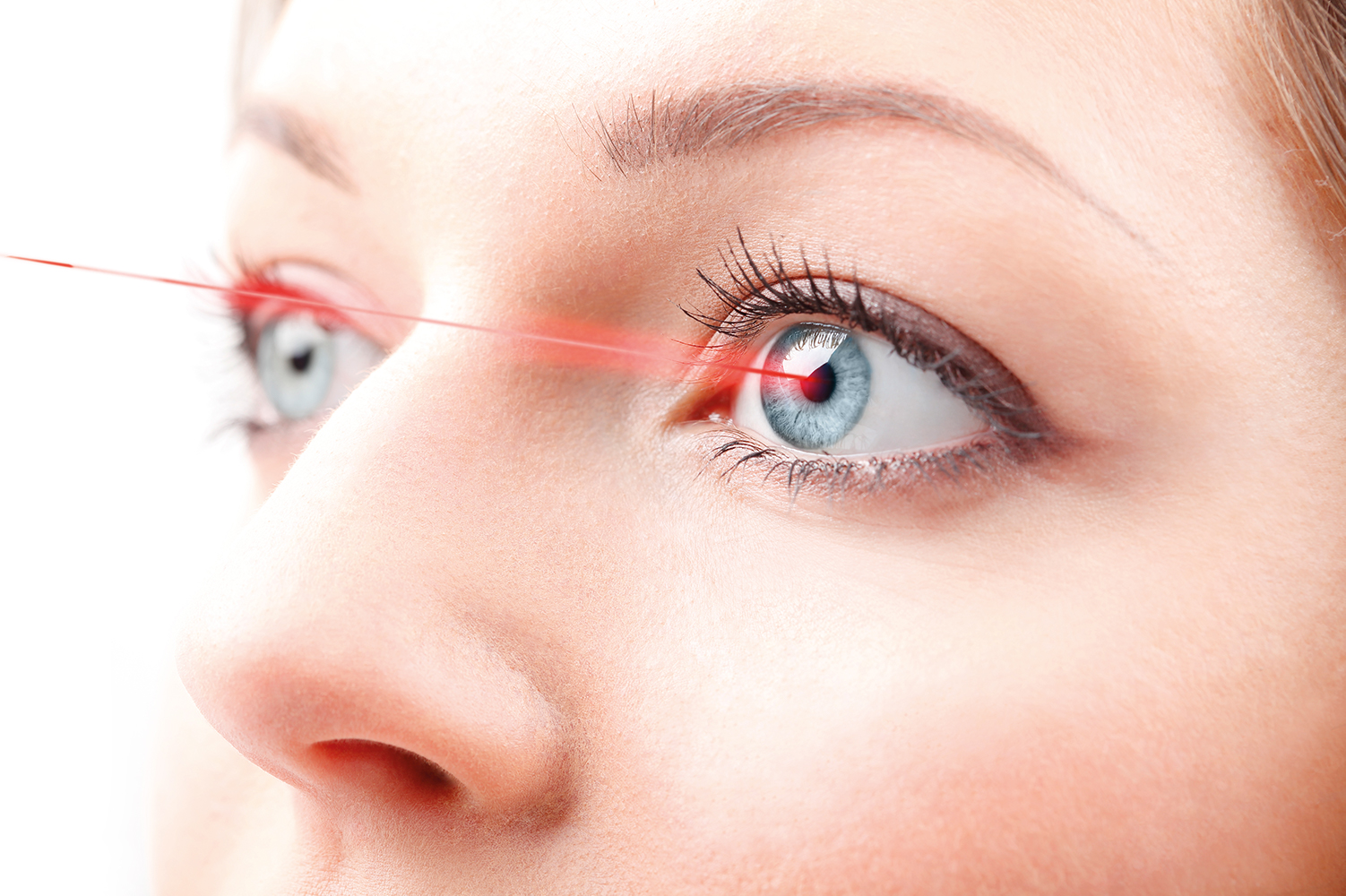

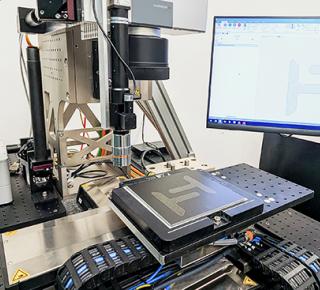

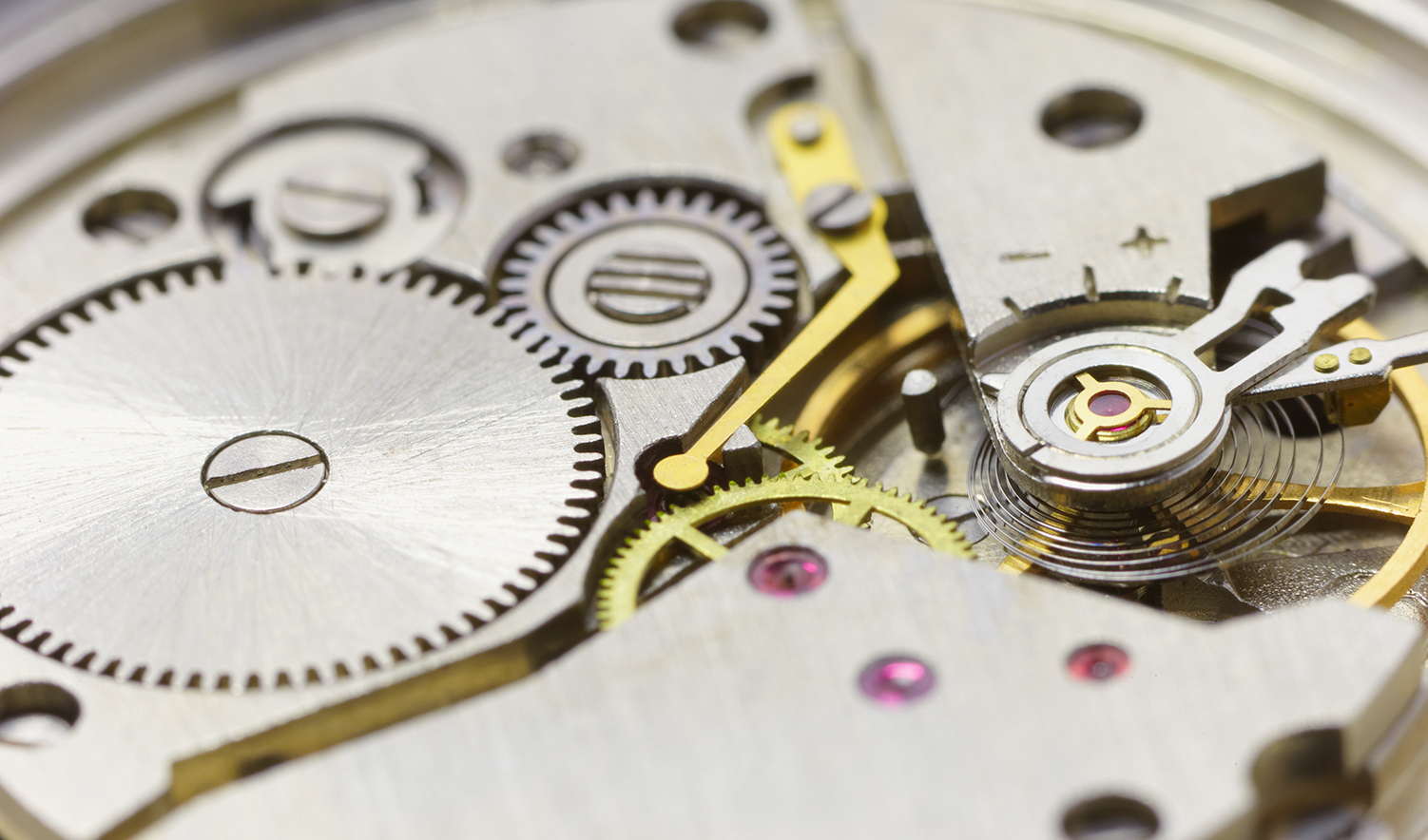

With tough requirements for machining delicate components and highly precious materials, the jewelry and watch-making industry is predestined to continue to rely on lasers. Furthermore, as a flexible tool, the laser is ideal for processing small quantities of workpieces. As a wear-free tool, the laser is ideally suited to processing metallic and crystalline materials. In combination with high-end scan heads and UKP lasers, the highest precision, accurate machining and finest structuring can be realized.

Especially in the lifestyle sector, the desire for individualized design is becoming ever greater. The laser helps to realize new ideas quickly, as it is only with the help of this technology that individual pieces can be produced economically.

Typical Laser Applications

-

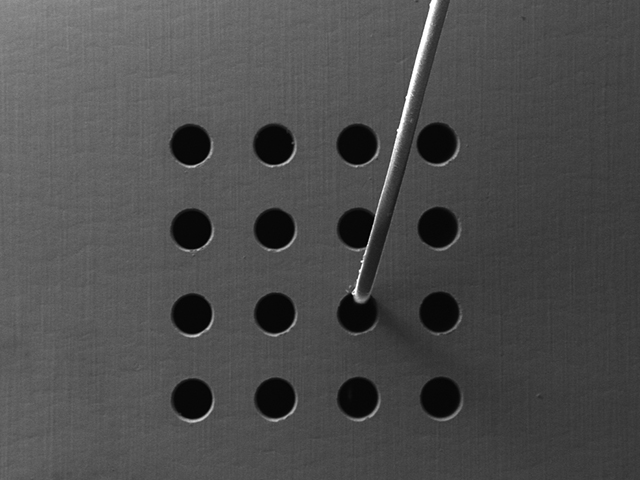

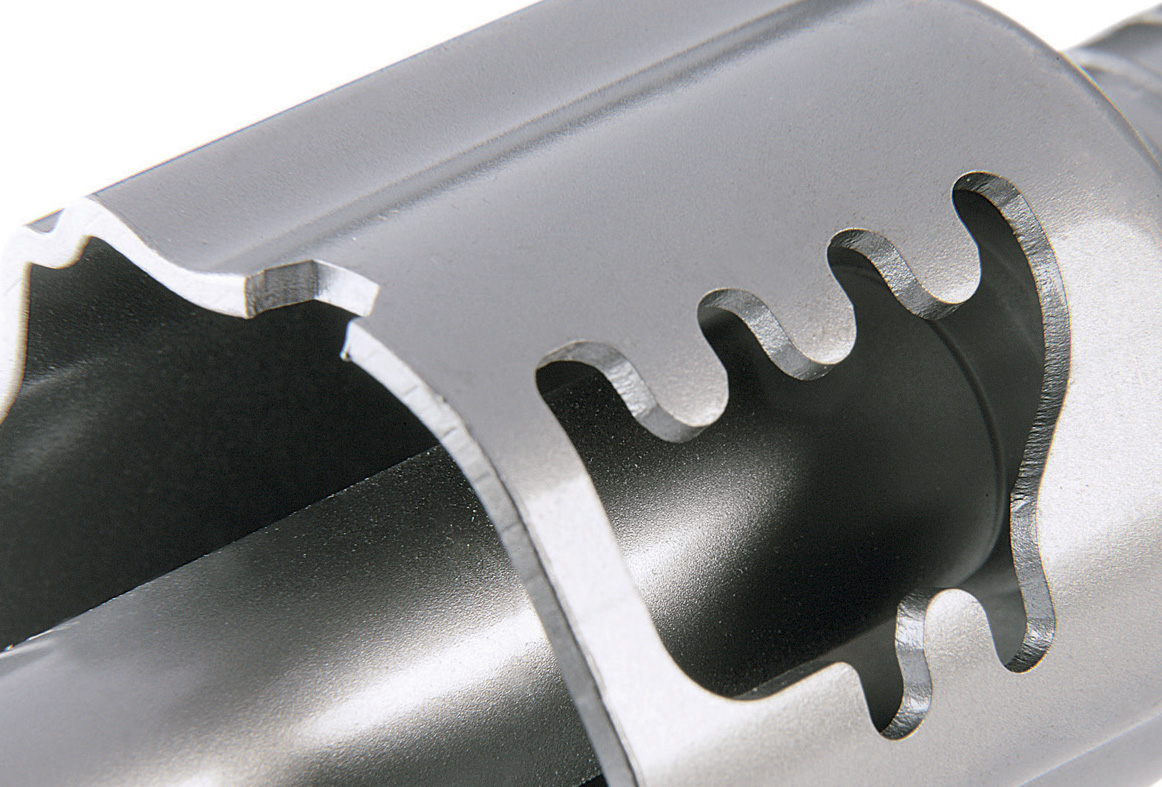

Laser cutting e.g. sapphire glass or tiny components such as pointers or gearwheels

-

Laser engraving e.g. subsurface glass engraving – for forgery-proof product labeling, large-area refinement or individualized laser engraving of jewelry, watches and smart devices

-

Laser structuring e.g. surface refinement and tool mould making for housings and jewelry pieces

-

Laser surface texturing e.g. surface modification for leather-like appearance

-

Laser sintering (3D printing) for individualized fabrication of single pieces

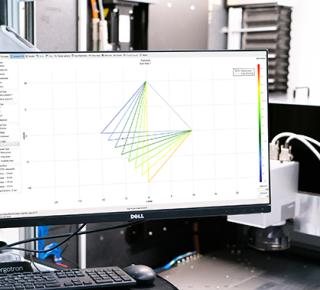

Lasers as Tools

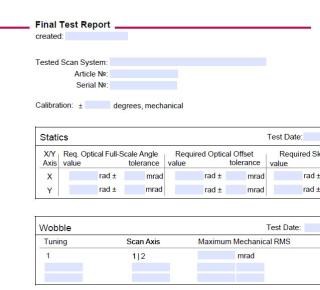

By transforming lasers into universal tools, scanning solutions help to add functionality and value to materials. SCANLAB's broad palette of scanning solutions fulfills demands for higher speed, more precision, greater efficiency or improved environmental compatibility.