Alternatively, these websites may already contain answers to the topic :

T

Tracking error

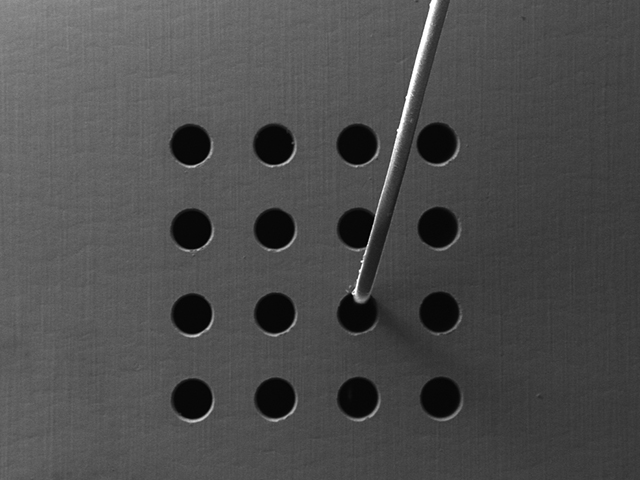

Tracking error is the time interval between the set and actual positions when traversing a vector.

What causes tracking error?

Because a scanner's mass inertia hinders it from instantaneously reaching the intended set position, it must accelerate and decelerate. A steady speed is desirable for laser marking, so the servo shouldn't attempt to overtake the set position during vector traversal. Instead, it needs to move at constant speed.

The time interval between the set and actual positions is called tracking error and is essentially independent of vector speed.

The spatial difference, i.e. the lag error, is proportional to speed.

The following applies: lag error = tracking error x speed.

A small tracking lag enables shorter scan delays and is thus advantageous for fragmented marking, but it limits the maximum speed. Depending on the application, a good match might be achievable through various tunings.

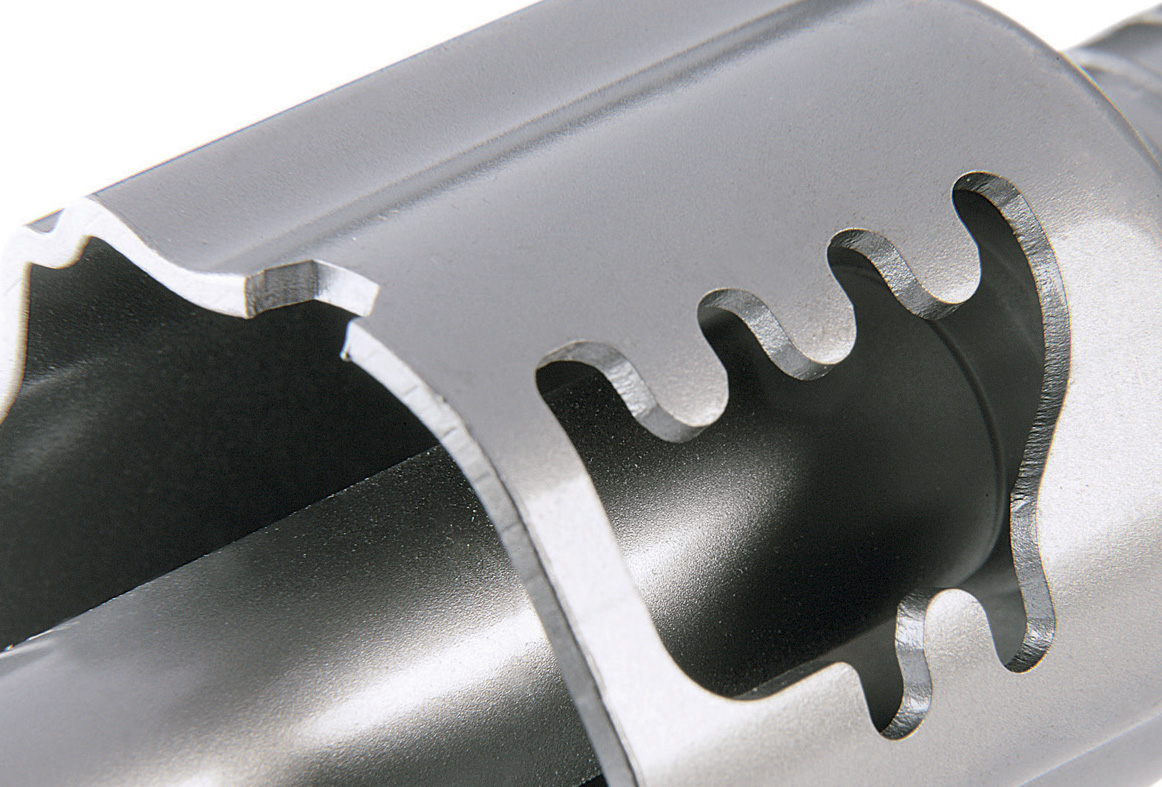

Lasers as Tools

By transforming lasers into universal tools, scanning solutions help to add functionality and value to materials. SCANLAB's broad palette of scanning solutions fulfills demands for higher speed, more precision, greater efficiency or improved environmental compatibility.